Controlled Environment Agriculture (vertical farms, modular greenhouses, indoor growing systems, etc.) is gaining traction globally. The promise is clear: fresh food, closer to the point of consumption, with dramatically less water and land use. But, the reality is still being built. Adoption is uneven, energy use remains a hurdle, and meaningful integration into food systems will require new thinking from technology partners, governments, and industry operators alike.

In this edition of Industry Signals, we look at four recent publications including Siemens’ 2025 trend forecast, peer-reviewed research, and global development case studies to grasp how CEA is evolving.

Key Ideas

1. Energy-smart farms are becoming the new baseline.

While CEA systems are resource-efficient on many fronts, they are often energy-intensive. Researchers point to the need for grid-responsive designs that can flex electricity use based on availability and price. Some startups are already building this in, creating farms that act as intelligent energy nodes rather than fixed consumers. The opportunity: align CEA with clean energy and smart grid strategies from the start.

2. Local-first doesn’t mean small-scale.

CEA often gets framed as either hyper-local or high-tech, but the most promising models combine both. We’re seeing modular, prefab growing systems deployed in schools, supermarkets, and even apartment complexes. In emerging markets, low-tech greenhouses with passive cooling systems and optimized light spectrums are showing strong yield gains—sometimes with as much as 90% less water than conventional agriculture. These should be considered blueprints for distributed food infrastructure.

3. Standards and interoperability will determine scalability.

For CEA to mature, systems across the value chain, from sensors and data collection to monitoring and analysis, must be interoperable. Shared standards enable smarter decision-making, ensure transparency, and reduce friction when integrating with other industrial and energy infrastructures. Without them, scaling CEA beyond isolated projects will remain difficult.

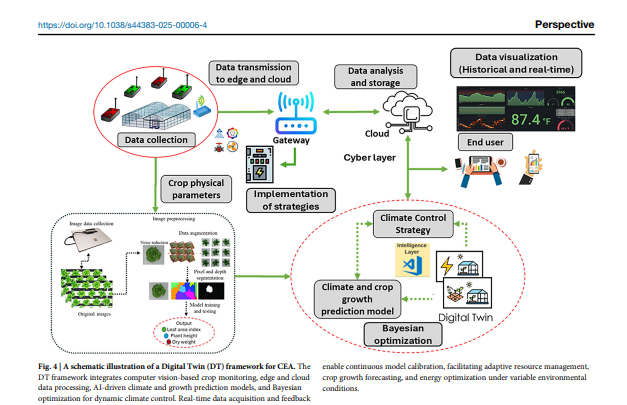

4. The digital twin of a lettuce leaf? Not far off.

CEA is a natural fit for digital twin technologies. By simulating crop growth, energy loads, and maintenance schedules, operators can test and adjust before a single seed is planted. Add to that the growing use of AI in environmental control systems, and the line between farming and industrial automation starts to blur—in a good way. This is precision agriculture reimagined indoors.

Siemens | Food and Beverage Trends for 2025

Source: Siemens | Published: January 9, 2025 Siemens’ 2025 outlook highlights a move toward traceability, proximity, and data-rich, digitally managed productions and operations. CEA supports year-round production near consumption hubs, cutting transport emissions, waste, and labor constraints while advancing automation, supply chain visibility, sustainability reporting, and workforce flexibility.

NPJ | Finding Sustainable, Resilient, and Scalable Indoor Agriculture

Source: npj Science of Plants | Published: July 1, 2025 This study underscores a core tension: while CEA reduces land and water use, its energy demands remain high. The authors call for grid-responsive operations, modular system design, and lifecycle-based planning, which help reduce operational costs and support scalability without energy performance tradeoffs. Notably, they position CEA as a potential grid asset, offering demand flexibility when paired with renewables and storage.

UNDP | Controlled-Environment Agriculture for Sustainable Development

Source: UNDP | Published: January 2025 UNDP highlights CEA models delivering real impact in low-resource settings and disrupted supply chains, from passive greenhouses in Jordan to aquaponic container farms in Kenya. These affordable and adaptable systems are already supporting food security, post-crisis recovery, and climate adaptation, and they can even cut water use by up to 98 percent. Scalable CEA is about smart, low-maintenance, site-specific designs and must be built for context. Global scale will come from modularity, local materials, and designs that work in the lab and the field.

Also worth checking out: The Journal of Horticulture Science and Biotechnology’s review on autonomous indoor farming, which highlights the use of digital twins and real-time feedback systems. What This Means for Industrial Innovators

CEA represents a convergence of domains that we already know well: grid-interactive energy systems, modular infrastructure, lifecycle optimization, and data-rich automation.

Here’s where industrial stakeholders can play a role:

- Design lifecycle-aware systems that minimize total energy and water use

- Enable remote monitoring and predictive maintenance through digital twins

- Support new deployment models: container farms, microgrids, pop-up food infrastructure

- Connect CEA operators with ecosystems of support—from financing to analytics to training

By embedding CEA into broader infrastructure strategies, we can help move it from pilot to platform.

Looking Ahead

CEA is not a one-size-fits-all solution, but it is a growing part of the food system portfolio, and especially in contexts where traditional supply chains are stressed or unreliable. For industrial innovators, the relevance lies not just in building the farms, but in connecting them to energy systems, digital infrastructure, and scalable service models.

We'll continue tracking signals at the intersection of food resilience, automation, and infrastructure innovation. If your team is working on solutions for distributed agriculture or modular food production, we’d like to hear from you.

That’s a wrap for this edition of Industry Signals.

Have a report, use case, or event you'd like to see featured in an upcoming issue? Send a note via PM. We’re always looking to spotlight what’s shaping the future of industry and find recommendations from the Xcelerator Community especially valuable. Your insights and experiences continually shape Industry Signals.

— Industry Signals Community Editor