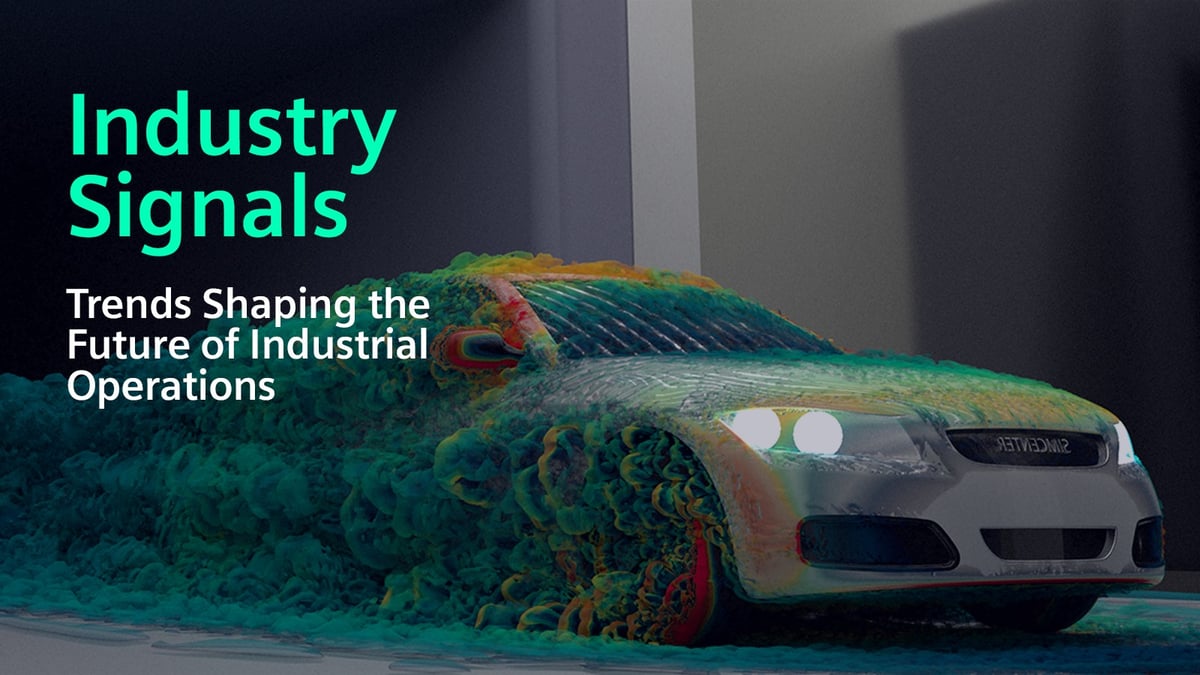

Welcome to this week's edition of Industry Signals, where we're exploring transformative trends reshaping the landscape of industrial innovation. In this edition, we explore three new reports by the World Economic Forum, Tata Consultancy Services, and Deloitte that underscore a common message: digital twins are no longer a future promise, but a present imperative.

At the center of this transformation is the convergence of technologies once considered siloed. Artificial intelligence, spatial intelligence, automation, and advanced materials are increasingly working in tandem, reshaping how factories, supply chains, and products operate and evolve. Digital twins now sit at the intersection of these forces, serving not just as virtual replicas but as dynamic, real-time platforms for insight, coordination, and continuous adaptation.

In this edition, we explore how:

- The World Economic Forum’s Technology Convergence Report positions digital twins as the connective layer in system-of-systems innovation.

- TCS’s Digital Twindex outlines how digital twins are enabling "Industry 4.5"—a new operating model defined by anticipatory intelligence, modular production, and AI-human collaboration.

- Deloitte’s latest Smart Manufacturing Survey highlights the growing operational and financial returns from digital twin deployments—and the strategic capabilities needed to scale them successfully.

Across these perspectives, one trend is clear: digital twins are becoming essential infrastructure for intelligent, resilient, and adaptive enterprise systems. The organizations that embed them into the core of their operating models will define the next era of industrial leadership.

Technology Convergence and the Key Role of Digital Twins: Insight from WEF's Technology Convergence Report

Source: World Economic Forum, Capgemini | Published: June, 2025 The World Economic Forum’s 2025 Technology Convergence Report, in collaboration with Capgemini, identifies how foundational technologies—such as AI, robotics, spatial intelligence, and advanced materials—are rapidly converging to reshape industries. The report introduces the 3C Framework (Combination, Convergence, Compounding) to analyze how these intersections create strategic value.

Highlights from the report include:

1. Digital Twin Ecosystems as Strategic Platforms

Digital twins are evolving into real-time, AI-enhanced, system-of-systems platforms. The report highlights how twins now integrate IoT data, physics-based simulation, and predictive analytics to enable operational optimization and lifecycle intelligence.

Implication: Digital twins are becoming central orchestration layers for enterprise-wide decision-making, not just engineering replicas.

2. Siemens Case Study: Industrial Metaverse Foundations

Siemens is embedding digital twin technologies into immersive environments, enabling simulation-informed control of products, factories, and infrastructure. This shift marks the move toward an industrial metaverse where AI agents automate adaptive operations.

Implication: Manufacturing leaders must prepare for a shift toward virtual-first design, production, and energy planning environments.

3. Compounding and Standardization Drive Strategic Advantage

As twin-enabled platforms gain adoption, standards, network effects, and ecosystem synergies are emerging. Companies that embed digital twins into their technology stacks early are better positioned to shape and benefit from these convergence effects.

Implication: Early movers will compound operational and strategic advantages, particularly in sectors with complex, asset-intensive workflows.

4. Cross-Sector Applications Expand the Relevance of Twins

Digital twins now underpin applications in healthcare (personalized diagnostics), biomanufacturing (precision fermentation), and energy (AI-optimized grids and emissions tracking).

Implication: Twin capabilities are increasingly essential for competitive differentiation in sustainability, resilience, and system-wide optimization.

2025 TCS Digital Twindex Report: Future-Ready Manufacturing

Source: TATA | Published: Q1, 2025

The 2025 TCS Digital Twindex report outlines a shift from traditional manufacturing models to what it terms "Industry 4.5", a transitionary era emphasizing real-time intelligence, AI-human collaboration, and sustainability. Digital twins are central to this evolution, serving not just as simulations but as enterprise-wide intelligence substrates that integrate with AI to orchestrate adaptive, anticipatory operations.

1. Digital Twins Are Becoming the Real-Time Data Fabric

Digital twins have evolved beyond static simulations to form the backbone of intelligent operations, connecting physical systems with AI in real-time. - Applications: Real-time diagnostics, synthetic data generation, and simulation for everything from individual assets to entire supply chains.

- Business Impact: TCS helped a global auto OEM achieve up to 30% efficiency gains through unified digital twin observability.

2. AI as the Orchestrator of Enterprise Intelligence

AI is no longer a discrete tool. Embedded within digital twins, it enables self-optimizing systems through predictive insights and autonomous decision-making.

- GenAI enhances interpretability and reasoning.

- Agentic AI enables autonomous agents to adapt based on real-time data.

- Physical AI bridges digital models with edge execution via Cobots and vision systems.

3. From Predictive to Anticipatory Manufacturing

Manufacturers are moving beyond predicting failures to preventing them proactively, thanks to agentic AI and continuous digital twin feedback loops.

- Use cases: predictive maintenance, dynamic workflow adjustment, AI-guided design and planning.

4. Modular and Distributed Manufacturing

The report outlines a shift to flexible micro-factories supported by digital twins and AI. These adaptive manufacturing nodes enable:

- Reduced CapEx and inventory

- Responsive, localized production

- Greater supply chain resilience and lower emissions

5. Human-AI Collaboration Is the New Competitive Edge

The future is human-led, AI-powered. AI copilots support operators with scenario planning, exception handling, and decision augmentation, not replacement.

- Key shift: From automation to augmentation, from interfaces to interaction, and from training to trust.

- Example: Jaguar TCS Racing uses digital twins for real-time simulation and strategy optimization—an approach now being mirrored in manufacturing environments.

Deloitte Smart Manufacturing Survey: Digital Twins at the Core of Smart Manufacturing Maturity

Source: Deloitte | Published: May 1, 2025

The 2025 Deloitte Smart Manufacturing Survey Report signals a pivotal shift: digital twins are no longer emerging tools—they are becoming foundational to how manufacturers orchestrate agility, optimize performance, and scale transformation. Based on insights from 600 senior manufacturing executives across sectors, the report shows that organizations that successfully embed digital twins into their smart manufacturing strategy are achieving measurable returns and laying the groundwork for more intelligent, responsive operations. Key Implications for Digital Twins

1. Digital Twins Are Becoming the Enterprise Nervous System

As manufacturers strive to move from reactive to anticipatory operations, digital twins are emerging as the data fabric connecting assets, processes, and systems across the value chain.

- 92% of executives believe smart manufacturing will be the leading source of competitiveness by 2027.

- Digital twins enable simulation, prediction, and optimization—key capabilities for navigating volatility and complexity.

2. ROI Is Driving Deeper Twin Integration

Digital twin implementations are already showing value, encouraging broader application.

- Reported improvements include 10–20% gains in output, 7–20% in employee productivity, and 10–15% in capacity utilization—benefits often unlocked through real-time simulation and process modeling.

- These results are pushing investment into supply chain, maintenance, and human capital twins, where maturity remains lower but potential is high.

3. Data Readiness and Connectivity Are Prerequisites

Smart manufacturing outcomes depend on digital twins that are continuously updated with accurate, structured data.

- Cloud (57%), IIoT (46%), and data analytics (57%) are widely adopted to enable real-time observability and feedback loops.

- However, only 41% of respondents prioritize factory automation hardware, and just 34% focus on sensors, both of which are critical components for achieving real-time twin fidelity.

4. AI and Digital Twins are Co-Evolving

Digital twins are most effective when paired with advanced analytics and AI—particularly for autonomous decision-making.

- 29% of companies use AI/ML and 24% use generative AI at scale, with an additional 38% piloting GenAI.

- AI extends the value of twins through predictive maintenance, defect detection, and adaptive planning, turning static models into intelligent systems.

5. Human Capital Remains a Bottleneck

Despite strong investment in twin technology, human capital lags in maturity, limiting adoption and impact.

- Only 48% of companies have a twin-related training/adoption standard.

- 35% cite worker adaptation to smart factories as a top challenge.

- Upskilling, not just technical deployment, will determine whether digital twins can be operationalized at scale.

6. Cybersecurity Risk Grows with Twin Maturity

As digital twins grow in scale and scope, especially at the plant or supply chain level, they introduce new cyber-physical vulnerabilities.

- 65% of executives cite operational risk—including unauthorized access (55%) and IP theft (47%)—as a top concern.

- Yet only 26% enforce secure-by-design practices if it might delay deployment, revealing a risk-prioritization gap that could hinder long-term scalability of twin systems.

7. Governance and Ownership Are Maturing

More than half of the respondents have created internal teams or Centers of Excellence to manage smart manufacturing transformation.

- 51% of twin-enabled initiatives are led by operations (COO), and 38% by technology leaders (CTO)—indicating growing IT/OT convergence.

- However, just 33% engage third-party partners for change management, suggesting internal capability gaps could limit broader adoption.

Survey Respondents Offer Guidance for Manufacturing Leaders

- Prioritize integration over experimentation: Scattered pilots won’t deliver transformative value—invest in end-to-end digital twin frameworks that connect design, production, supply chain, and maintenance.

- Elevate data and infrastructure maturity: Without real-time, structured data flowing across systems, even the best twin models will fail to reflect operational truth.

- Pair twin deployment with workforce development: Upskill the workforce to not only use digital twin insights but to co-evolve alongside intelligent systems.

- Harden cybersecurity posture: As twins scale, so does exposure. Embed secure architecture and risk management from the start.

- Make digital twins a pillar of business strategy: The most competitive firms are not just digitizing—they are designing adaptive enterprises with digital twins at the center.

That’s a wrap for this edition of Industry Signals.

Have a report, use case, or event you'd like to see featured in an upcoming issue? Send a note via PM. We’re always looking to spotlight what’s shaping the future of industry and find recommendations from the Xcelerator Community especially valuable.

— Industry Signals Community Editor