Innovation and Future Resources

July 22, 2025

Industry Signals - July 22, 2025: The Future of Work: Taking a Human-Centered Approach to Industrial Intelligence

# AI

# Automation

# Digital Manufacturing

# Digital Transformation

# Higher Ed

# Industrial AI

# Key Trends

The trends driving the Future of Work are redefining how manufacturers operate: integrating human-centered automation, digital skills, and organizational agility to unlock productivity, workforce resilience, and long-term competitiveness.

Industry Signals

Welcome to another edition of Industry Signals. In this issue, we examine the Future of Work in industrial and manufacturing settings: a transformation as profound as any technological disruption, driven by the convergence of AI, automation, digital upskilling, and workforce demographic shifts. As these forces move from pilots to scaled implementation, workforce strategy is emerging as a defining pillar of industrial competitiveness, blending productivity gains with adaptability, resilience, and long-term talent sustainability.

The insights in this edition cut through the noise of workforce anxiety or automation hype. The trends driving the Future of Work are already reshaping shop floors and innovation centers, elevating human capabilities through digital tools, expanding talent pipelines through inclusive upskilling, and repositioning workforce investment as a strategic asset rather than a cost center.

Inside, you’ll find critical insights drawn from recent publications:

- The World Economic Forum’s Future of Jobs Report 2025 projects a net gain of 78 million jobs by 2030, driven by green growth, AI adoption, and demographic shifts, while emphasizing the urgency of reskilling.

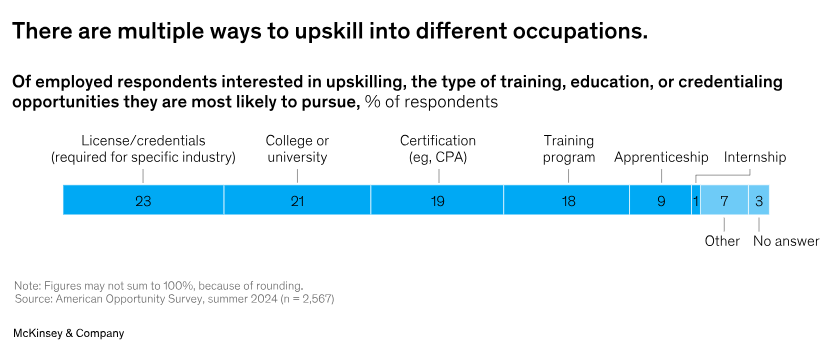

- McKinsey’s Upskilling Imperative highlights a workforce eager to adapt, with strong interest across age and demographic groups, and also identifies cost and time as primary barriers, underscoring the need for employer-led, flexible learning models.

- PwC’s Global AI Jobs Barometer reveals that AI-augmented roles are expanding, not vanishing, with a 56% wage premium for AI-proficient workers and 4x productivity gains in industries that embrace digital reinvention.

- Deloitte’s 2025 Smart Manufacturing Survey affirms that 92% of manufacturers view smart technology as the key to competitive advantage, and yet many still lag in workforce readiness, change leadership, and cybersecurity investment needed to translate digital promise into operational value.

Together, these insights underscore the Future of Work not as a future event, but as a present-day imperative, requiring industrial leaders to embed workforce strategy into digital transformation, build adaptive cultures of learning, and harness technology to elevate (not eliminate) human potential. The future of industrial work is here, and it’s being built by the choices we make today.

The Imperative for a Human-Centric Industrial Transformation

Manufacturing is entering a pivotal chapter in its evolution: one often characterized as the Fourth Industrial Revolution, but increasingly, as we will highlight in this edition of Industry Signals, it may be better seen as a Human-Centric Industrial Transformation. Over the next few years, the factories and companies that flourish will be those that skillfully blend technological prowess with human ingenuity. It is clear that the Future of Work in industrial settings is not a distant concept; it is unfolding right now on factory floors, in supply chain hubs and R&D labs, and wherever people and machines interact to make the goods that power our economy. We have seen that automation and AI are not eliminating industrial work. Instead, these technologies are transforming it, often in ways that elevate the role of human workers.

Manufacturers who turn workforce challenges into opportunities by innovating in training, redesigning jobs, and creating environments where humans thrive alongside increasingly sophisticated machines will reap great rewards. The risks of inaction (or wrong action) include eroding competitiveness due to talent shortfalls, employee discontent, and underutilized expensive tech. But the opportunities are immense: higher productivity, new revenue streams (from innovative products enabled by skilled teams and advanced tools), and a revitalized manufacturing sector that can attract the best and brightest.

Upskilling at Scale and the Future of Occupational Mobility: Insights from McKinsey on Workforce Readiness, Equity, and Employer-Driven Training Models

McKinsey & Company’s research report on the Upskilling Imperative discusses a key problem: a diverse and motivated talent pool is ready to upskill, but the pace is hampered by practical constraints like time and cost. Now is the time for organizations to design flexible, occupation-aligned training solutions, integrating learning into daily work life and subsidizing costs because doing so can unlock workforce potential and readiness for the rapidly evolving job landscape.

Highlights from the report include:

Broad Willingness to Upskill Across Demographics

- High interest across the board: 42% of survey respondents are seeking upskilling, especially young workers (63% of those aged 18‑24; 53% of 25‑34).

- Strong diversity in interest: Black (54%), Hispanic (49%), Asian American/Pacific Islander (49%), lower-income (<$50K), urban, and immigrant workers show higher interest, 8–16 points above their counterparts.

Major Barriers: Time and Money

- Top obstacles: Nearly 50% cite lack of time and financial cost as key challenges.

- Specific constraints:

- Time barriers are especially acute for higher-income (>$100K) and mid-career workers (35–64).

- Other challenges include transportation, lost wages, and mental health barriers (around 10% overall; nearly double for younger workers).

Employers and NGOs as Key Enablers

- Preferred Support Providers: Among those looking to upskill, 41% favor educational institutions, 35% look to private companies, and 23% to non-profits. Even those not yet planning to upskill (32%) would seek company support.

- Opportunity for workplace-based upskilling: Providers that integrate training into work schedules and share costs are well-positioned to tap into employee motivation.

Tailored Delivery Models

- Customize learning formats: Employers and NGOs can increase accessibility via:

- Part-time or self-paced programs

- Free video series

- Flexible schedules or transport support

- Older workers prefer platforms like Coursera, while younger workers engage more with LinkedIn or YouTube content

Alignment with Occupational Goals

- Diverse upskilling formats based on career path:

- Certifications are favored for business/finance roles

- Licensing and tailored training are preferred for managerial roles

- Strategic outreach: Programs should target motivated individuals (via career fairs, referrals, and alumni networks) to build scalable pipelines.

Urgency and Potential of Occupational Mobility

- Heightened readiness: Americans show unusually high willingness to switch occupations, more than in many other advanced economies.

- Upskilling as a catalyst: Removing time and cost barriers could unlock significant occupational mobility and better align workforce skills with future jobs.

Job Displacement, Creation & Skill Reinvention: Insights from WEF’s Future of Jobs Report 2025 on Tech, Green Transition, and Workforce Transformation

The findings in The World Economic Forum’s Future of Jobs Report spotlight not just a shift in which jobs will grow or vanish, but also underscore the scale of upskilling needed and the changing nature of work, blending automation with human skills in a rapidly evolving economy.

Highlights of the report include:

Transformative Macro‑Trends

By 2030, global labor markets will be reshaped by technological advances (AI/robotics), geoeconomic fragmentation, demographic shifts, the green transition, and rising living costs.

Net Job Growth with Massive Shift

Expected workforce transformation: ~22% of today’s jobs; 170 million new jobs created, 92 million displaced for a net gain of 78 million roles.

Fastest-Growing Roles

Tech roles (AI/ML specialists, Big Data experts, software engineers), green jobs (renewable energy, EV specialists), and human-centric roles (nurses, social workers, delivery/construction workers) are in high demand.

Emerging Skill Demand

High-growth skills include analytical thinking, resilience, AI/big-data literacy, cybersecurity, creativity, lifelong learning

Upskilling Imperative

85% of employers plan to upskill/reskill workers. Training focuses on AI, digital, green technologies, and soft leadership skills.

Automation vs. Augmentation

Human-only tasks will drop from 47% to 33%; automation takes 34%, while human–machine collaboration rises to 33%.

Economic & Geopolitical Pressures

Half of businesses cite cost-of-living pressures and slower economic growth as disruptive, while ~34% foresee geoeconomic fragmentation driving reshoring and increased demand for cybersecurity and adaptive leadership.

Demographic Dynamics

Aging populations in high-income countries boost demand for healthcare and talent development. Meanwhile, young workforces in emerging economies fuel growth in education and training roles.

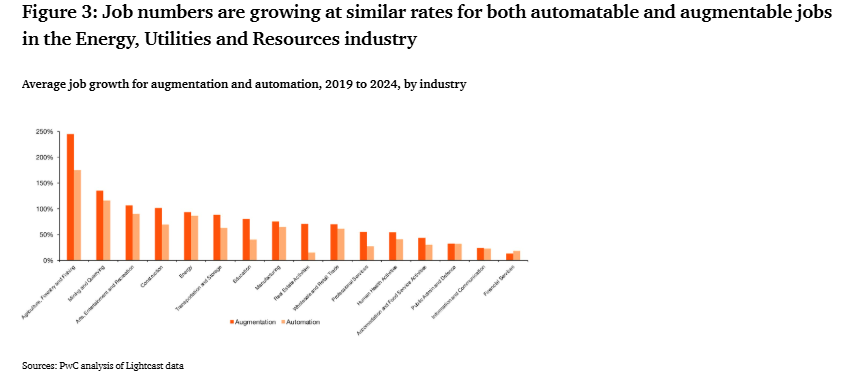

AI as Amplifier, Not Eraser: Insights from PwC's 2025 Global AI Jobs Barometer on Jobs, Wages, and Workforce Resilience

PwC’s 2025 AI Jobs Barometer reveals that AI is accelerating productivity, wage growth, and job creation, especially in roles once considered automatable, while rapidly reshaping required skillsets. For industrial and manufacturing sectors, this underscores a strategic imperative to deploy AI as a workforce amplifier, not a job replacer, and to invest heavily in upskilling to remain competitive.

AI-Augmented Productivity

- Manufacturers that adopt AI (especially predictive maintenance, generative design, and quality control) can achieve substantial gains in output per worker.

- Early adopters in manufacturing may mirror the 4x productivity growth seen in finance and tech.

Talent Premium for AI-Skilled Operators and Engineers

- Mechatronics engineers, automation technicians, and data-savvy maintenance workers with AI literacy are commanding premium wages.

- Plants that fail to upskill workers for AI-integrated operations risk falling behind in talent attraction and retention.

Growth in “Automatable” Yet AI-Augmented Roles

- Roles like equipment operators, quality inspectors, and schedulers are not disappearing. They’re being enhanced through AI copilots and computer vision systems.

- Industrial job growth is not threatened where AI is used to augment humans, not replace them.

Rapidly Shifting Skill Profiles

- Manufacturing skill demands are changing ~60% faster in AI-augmented roles (e.g., from mechanical-only to data+mechanical hybrid roles).

- Continuous learning platforms and micro-certifications are now essential to stay ahead of role obsolescence.

Adoption of Agentic AI on the Shop Floor

- Agent-based systems (e.g., autonomous scheduling, AI-driven visual inspection agents) are being deployed to oversee line operations, supply chain flows, or maintenance cycles.

- These agents shift shop floor management from reactive to predictive, increasing resilience and efficiency.

Strategic Reframing of AI in Manufacturing

- AI should not only reduce costs (e.g., labor, defects) but enable:

- Faster design-to-manufacture cycles (via generative engineering)

- Smart, modular production (via intelligent scheduling agents)

- Predictive supply chain resilience (via demand-sensing AI)

- AI’s ROI is maximized when integrated across design, production, and logistics, not siloed in IT or R&D.

Smart Foundations, Agile Factories: Insights from Deloitte’s 2025 Survey on Workforce, Tech, and Resilience in Smart Manufacturing

We included Deloitte’s 2025 Smart Manufacturing Survey in our recent edition of Industry Signals on the topic of Digital Twins, and we feel like it is a key piece to include here again because it reveals that, despite smart factory initiatives delivering clear productivity, capacity and agility gains, manufacturers still lag in workforce readiness, change management and cybersecurity, all of which are topics related to the Future of Work. Technological foundations must be paired with strategic talent, risk and organizational investments to convert smart investments into tangible business value.

Highlights from the survey include:

Widespread Smart Manufacturing Adoption

92% of surveyed manufacturers view smart manufacturing as the top lever for competitiveness over the next three years, with 85% believing it will transform production, agility, and talent attraction.

Strong Performance Gains

Companies already using smart technologies report:

- 10–20% increases in production output

- 7–20% uplift in employee productivity

- 10–15% additional unlocked capacity

Significant Investment Commitment

78% of respondents allocate over 20% of their improvement budgets to smart manufacturing, and 88% plan to maintain or increase that investment.

Human Capital Remains a Weak Spot

Human capital, material management, and maintenance are the least mature functions with 35% identifying adapting workers to “Factory of the Future” as a key challenge.

Automation & Data at the Core

Nearly half prioritize process automation; 37% focus on physical automation; investments heavily favor data analytics (40%), cloud and AI (29% each), and IIoT (27%).

Risks: Operational Disruption & Cybersecurity

65% see operational risk (project failure/disruption) as a primary concern, and cybersecurity breach remains a top risk requiring attention.

Dedicated Change Teams Established

Over half (52%) have set up central teams to guide smart manufacturing initiatives, often led by COOs (51%) with CTOs (38%) playing key roles

Looking Ahead

The factory of the future will not be run by robots, but by enlightened companies that know how to harness robots and humans together. Those who get this right will unlock levels of efficiency, innovation, and agility that set them apart. Those who do not will struggle to compete, as talent and technology both become limiting factors.

In conclusion, the future of work in industrial manufacturing is being written by the decisions industry leaders make today. By focusing on both cutting-edge tech adoption and robust people development, manufacturers can ensure that this future is one of sustainable growth, shared prosperity, and exciting new possibilities, for businesses and workers alike. The choice is ours to make: champion a human-centric innovation journey and lead our companies into the next industrial era, or cling to outdated paradigms and be left behind. The evidence and insights compiled here strongly suggest the former path is the one that will drive enduring success.

That’s a wrap for this edition of Industry Signals.

Have a report, use case, or event you'd like to see featured in an upcoming issue? Send a note via PM. We’re always looking to spotlight what’s shaping the future of industry and find recommendations from the Xcelerator Community especially valuable. Your insights and experiences continually shape Industry Signals.

— Industry Signals Community Editor

1

Comments (0)

Popular

Popular

Dive in

Related

Blog

Industry Signals - July 8, 2025: Industrial Electrification: Implications, Risks, and Strategies for Manufacturing’s Sustainable Future

By Industry Signals • Jul 8th, 2025 • Views 247

Blog

Industry Signals – August 5, 2025: Smart Manufacturing at the Crossroads of Technology, Resilience, and Human-Centric Innovation

By Industry Signals • Aug 5th, 2025 • Views 158

Blog

Industry Signals – October 7, 2025: How Industrial Leaders Are Rewiring for AI

By Industry Signals • Oct 7th, 2025 • Views 86

Blog

Industry Signals - June 24, 2025: Unlocking the Industrial Metaverse & Accelerating Digital Transformation Across Industries

By Industry Signals • Jun 24th, 2025 • Views 136

Blog

Industry Signals - July 8, 2025: Industrial Electrification: Implications, Risks, and Strategies for Manufacturing’s Sustainable Future

By Industry Signals • Jul 8th, 2025 • Views 247

Blog

Industry Signals – October 7, 2025: How Industrial Leaders Are Rewiring for AI

By Industry Signals • Oct 7th, 2025 • Views 86

Blog

Industry Signals - June 24, 2025: Unlocking the Industrial Metaverse & Accelerating Digital Transformation Across Industries

By Industry Signals • Jun 24th, 2025 • Views 136

Blog

Industry Signals – August 5, 2025: Smart Manufacturing at the Crossroads of Technology, Resilience, and Human-Centric Innovation

By Industry Signals • Aug 5th, 2025 • Views 158